[QUOTE=crazyjay;3604354]inside that corner of the oil pan is there anything

(sump/pickup) that would stop you from making a small dimple in the pan to

just give some extra room there?? better you do it now then have something

(engine torque/ bad engine mount) do it later and possibly puncture through and

make this whole build meaningless.

also with regards to your alternator bracket; there is going to be some

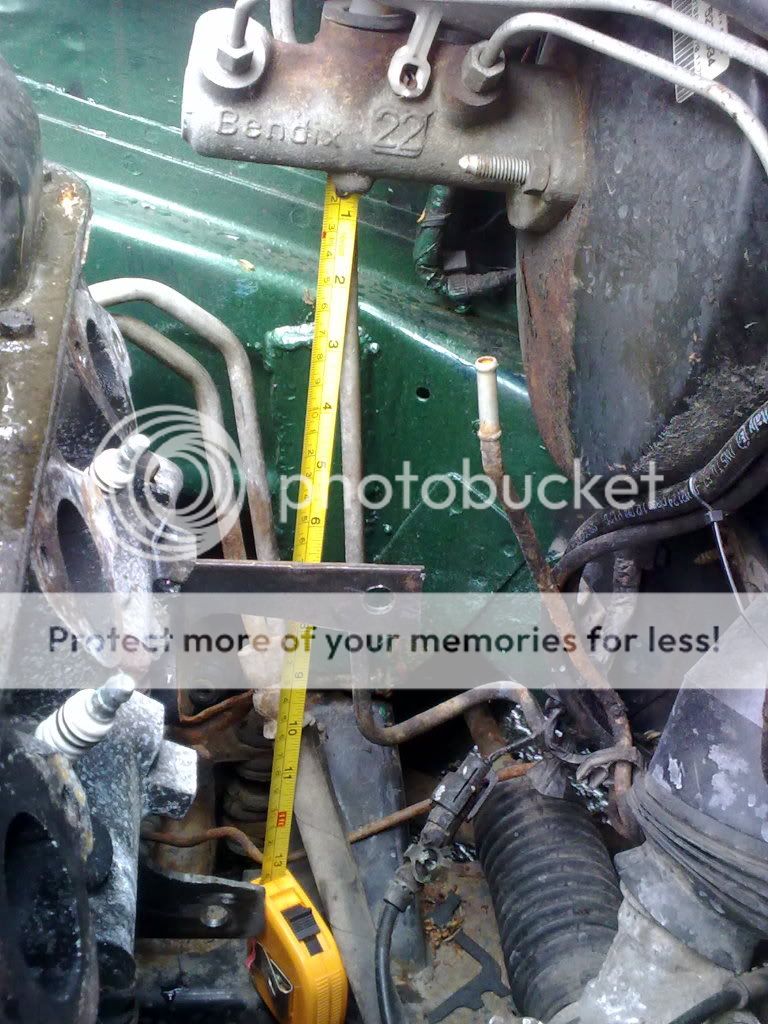

suspension travel and your driveshaft is going to move up and down. is there going

to be enough clearance for the shaft to move through that opening safely without hitting?

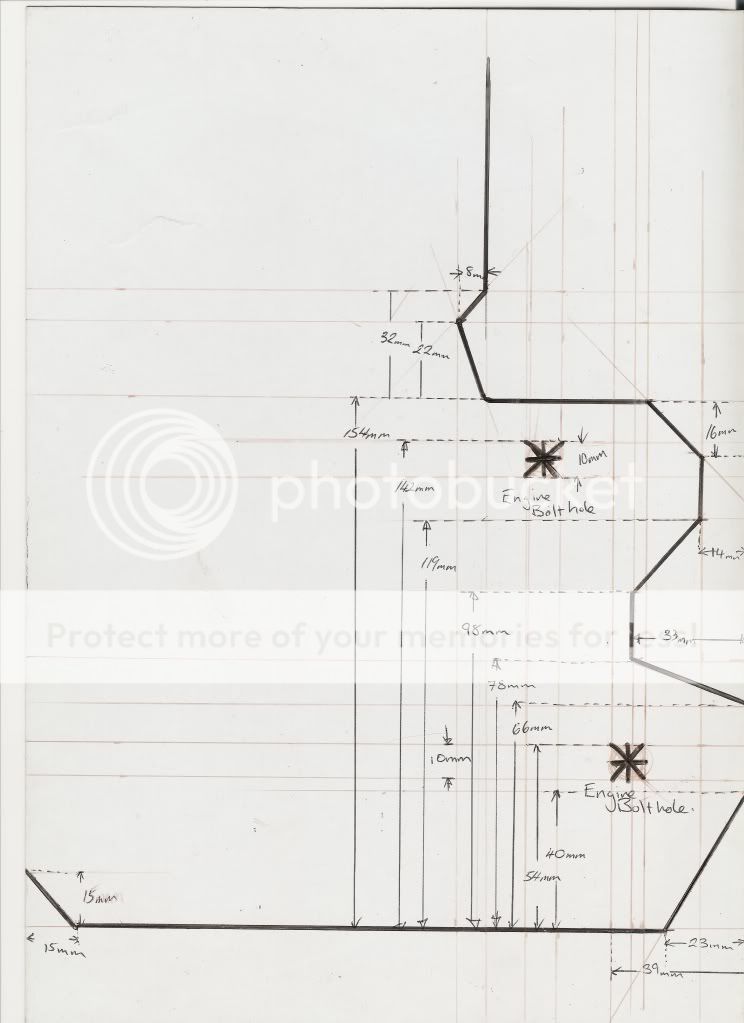

and in respect to the subframe and gearbox; with the heavy steel you are using

could you not make a small cut out in the subframe and weld in a relief so that

there would be the room you need to clear. that heavy steel should help the

integrity of the subframe and keep it solid.

[/QUOTE]

[/QUOTE]

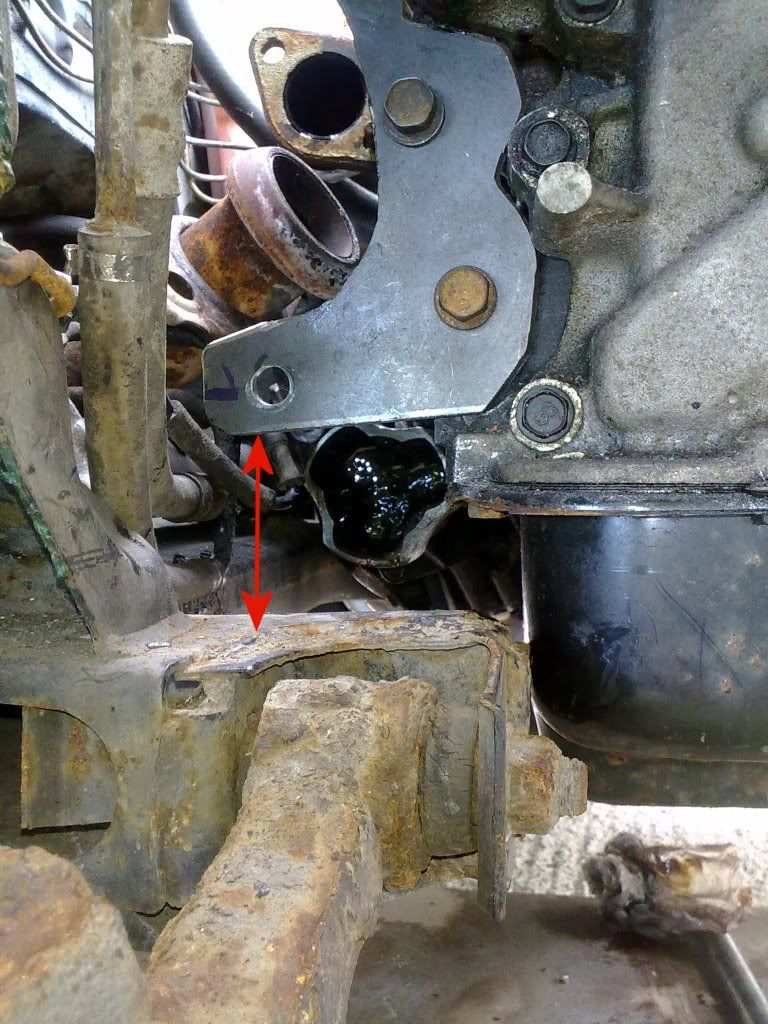

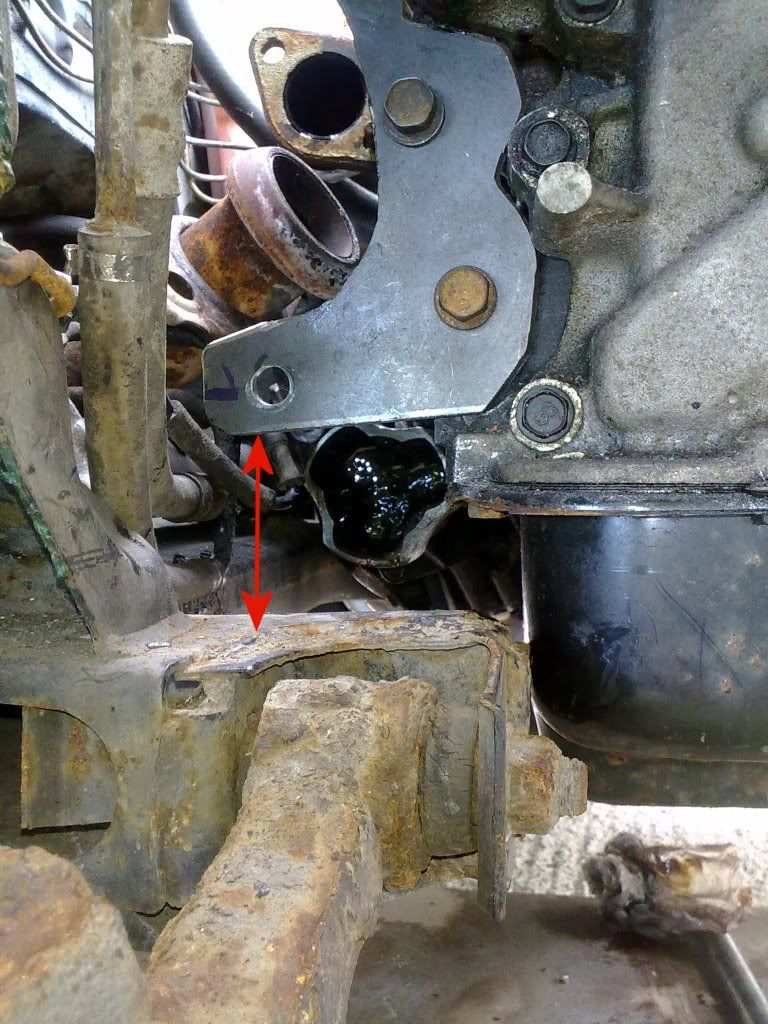

First the alternator bracket is not final and can be altered or scrapped for a

new setup to be planned. So the red arrow in the picture below might not be

the final space for move ment of the drive shaft

Crazyjay I hadn't thought about

" a small cut out in the subframe and weld in a relief so that there would be the

room you need to clear. that heavy steel should help the integrity of the subframe

and keep it solid."

As my father is the welder I have put the idea to him and he will decide if he

can do it.

And

"inside that corner of the oil pan is there anything (sump/pickup) that would

stop you from making a small dimple in the pan to just give some extra room

there??"

I too have been thinking about this I will be taking the oil pan off in the next few

days to do an oil change and check whats in the pan so I will find out then.

The guy at the radiator place in Thornaby gave me a price for a custom radiator.

£250 plus vat (tax at 20%) which is 408.156 USD

A little expensive for my tastes, I will get a few more quotes!

And mothers car broke down on the way back from Thornaby,

It wasn't the battery that was at fault but the power lead connection at the alternator.

There was no dash warning as the alternators signal wires were ok and so was the

alternator.

And where did the car brake down but at a junction with traffic lights on the other side

of an under pass and a bad bottle neck for traffic and it is a very bussy intersection.

As it also had a little slop back to where I had just come from I had to wieght for some

helpfull gentlemen to push the car onto the pavement(my legs aren't fit for purpose

most of the time so I couldn't get out and push.

I opened the manual sunroof as the windows were electric and didn't work and put my

arm through it to signal to vehicles behind to go around as the hazard warning

lights wouldn't work.

I caused caouse for about 30 min before I was moved, but you always get a few

who don't understand hand signals

(which were part of the driving test when I took it)

and pull up bumper to bumper and blast their horns and expect you to get out of the way,

and the language from those were bad.

All the proffesional drivers were fine, understanding hand signals and giving tumbs up

acknowledging that I was doing everything I could to divert them arround the car and

not just abandon it there.

The RAC (Royal Automobile Club) were good and quick, They goty the car fixed (no

tools in the car so couldn't do it)

And the wire was in the worst spot to get to to re-attach, so hopefull thats it for a while

with it being a pain I can get on with mine again!