V6 into a RHD Chrysler Neon mk1

- SirTainleyBarking

- Posts: 413

- Joined: Mon Feb 14, 2011 12:41 am

- Location: Solihull, where Landrovers come from

Re: V6 into a RHD Chrysler Neon mk1

Colour match it to the rest of the car

Landrovers and Welding go together like Bread and Butter. And in the wet they are about as structurally sound

Biting. It's like kissing except there's a winner

Biting. It's like kissing except there's a winner

Re: V6 into a RHD Chrysler Neon mk1

No as the car is dark green, you can have too much of a good thingSirTainleyBarking wrote:Colour match it to the rest of the car

I'm Diabetic,& disabled BUT!! NOT DEAD YET!!

Re: V6 into a RHD Chrysler Neon mk1

Heliotrope would suit it well, IMHO.

J

"Home is where you park it", so the saying goes. That may yet come true..

"Home is where you park it", so the saying goes. That may yet come true..

Re: V6 into a RHD Chrysler Neon mk1

A little looking at the recently received inlet manifold,

it doesn't have an exhaust gas return inlet on it!

I got hold of the gasket off the neon's and used that.

I drilled and tapped the two bolt holes.

All I need to do is flatten the surrounding area for a

flush fit for the pipe.

A new problem has arisen, top is the 93 map sensor &

below it the one the ecu was using in the original 98

manifold. Looks like either making the newer 98 map fit

the old hole and drill/tape two fixing bolt holes.

Or blank that hole and fit it elsewhere!

I'll look at the manifold again in the morning.

it doesn't have an exhaust gas return inlet on it!

I got hold of the gasket off the neon's and used that.

I drilled and tapped the two bolt holes.

All I need to do is flatten the surrounding area for a

flush fit for the pipe.

A new problem has arisen, top is the 93 map sensor &

below it the one the ecu was using in the original 98

manifold. Looks like either making the newer 98 map fit

the old hole and drill/tape two fixing bolt holes.

Or blank that hole and fit it elsewhere!

I'll look at the manifold again in the morning.

I'm Diabetic,& disabled BUT!! NOT DEAD YET!!

Re: V6 into a RHD Chrysler Neon mk1

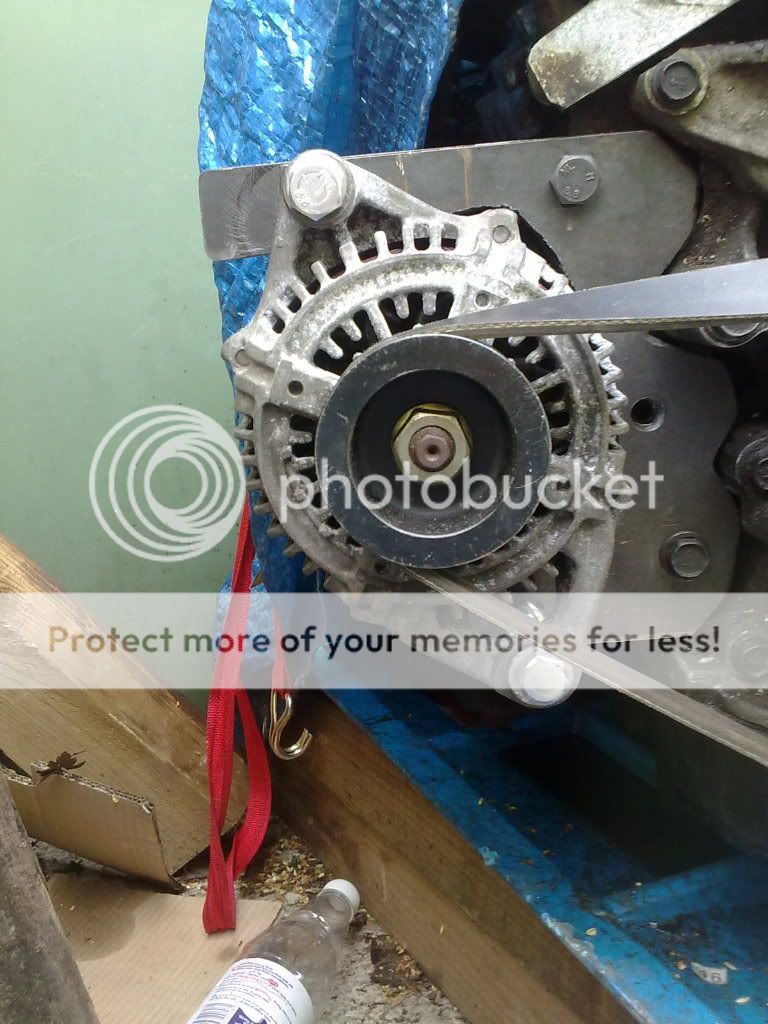

The dorman 300-308 power steering pulley arrived,

so i spent a little time fitting that to the pump.

I might have to use some washers between the bracket,

and the pump to bring it inline for the belt.

And now back to the planned task of the day the

alternator bracket.

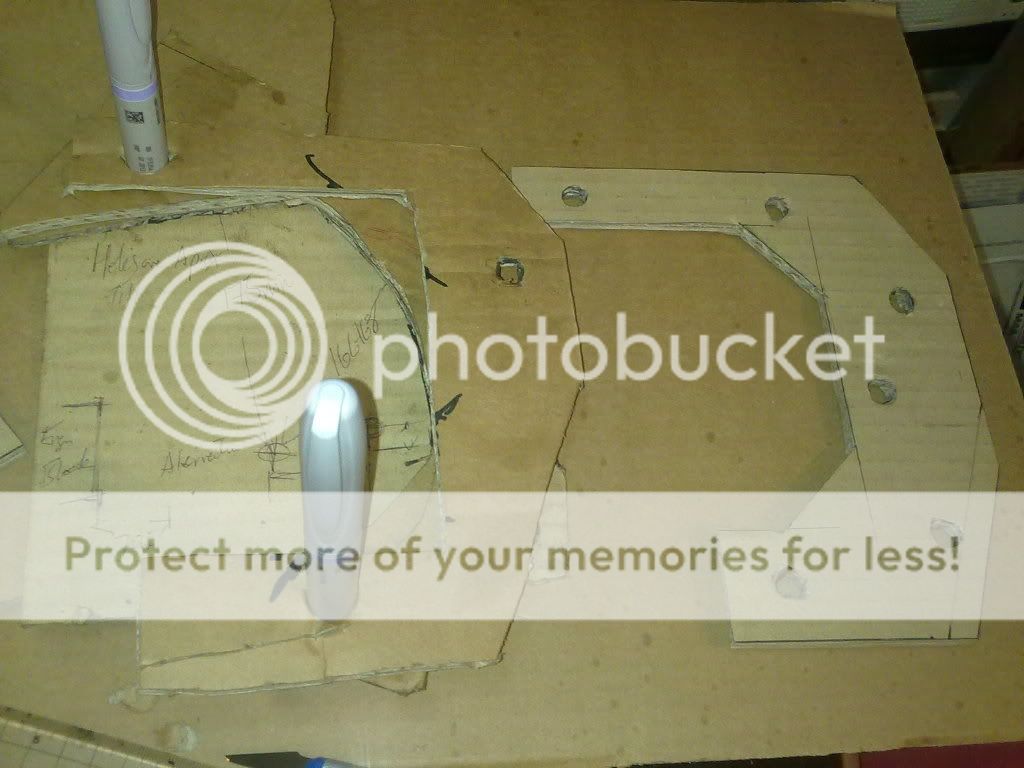

in the picture below a metal plate is bolted up and then it's

cardboard template.

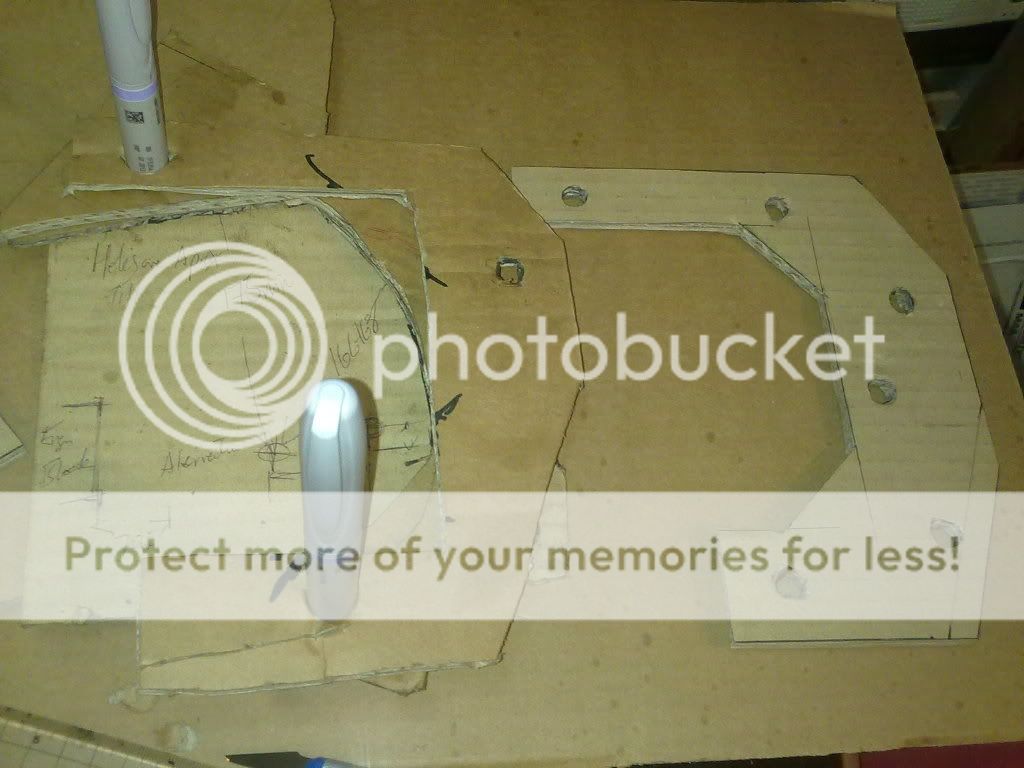

In front of the blank template is a cardboard template for the

back plate for the alternator. Both templates that are for

going around the aletator are not full templates for the full

metal plates.

Now we have the front template for going around the front

part of the alternator

All the partial templates lined up back to front.

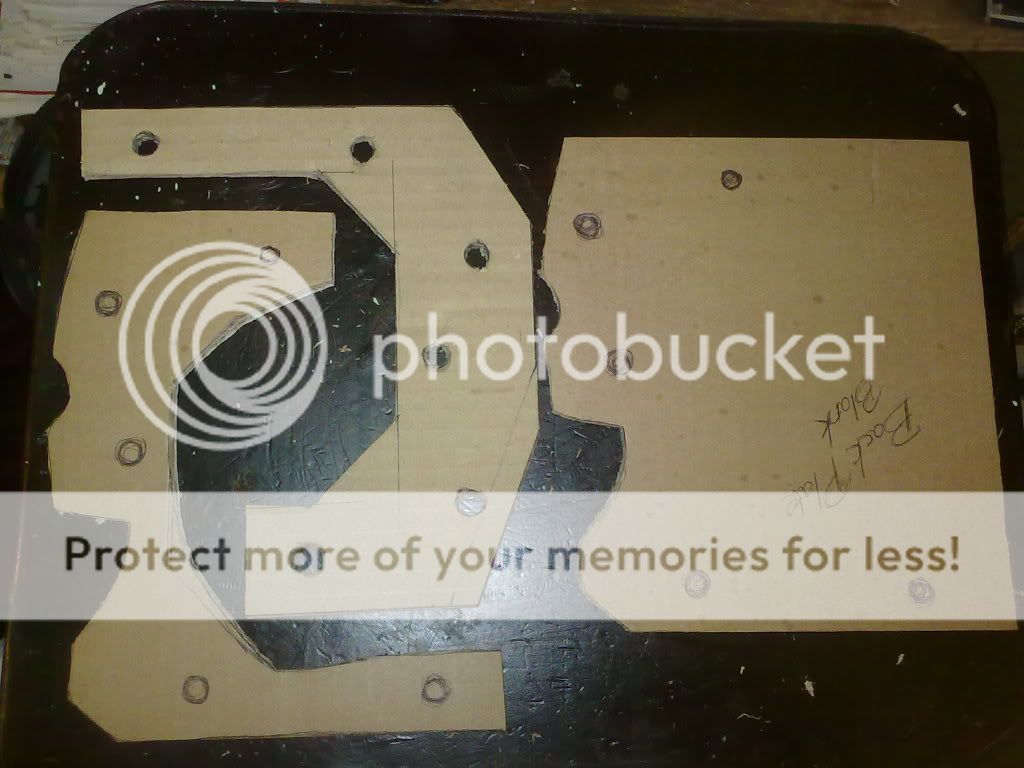

Now with the metal blanks drilled and marked ready for cutting

out tomorrow weather permitting.

There will be a bit of piping s a spacer which will be to protect

the bolts going through and act as a spacer between the fron

and back sections of the bracket.

Making it in a few sheets of metal means it will be easier to make,

and stronger once welded together so it won't warp and twist.

so i spent a little time fitting that to the pump.

I might have to use some washers between the bracket,

and the pump to bring it inline for the belt.

And now back to the planned task of the day the

alternator bracket.

in the picture below a metal plate is bolted up and then it's

cardboard template.

In front of the blank template is a cardboard template for the

back plate for the alternator. Both templates that are for

going around the aletator are not full templates for the full

metal plates.

Now we have the front template for going around the front

part of the alternator

All the partial templates lined up back to front.

Now with the metal blanks drilled and marked ready for cutting

out tomorrow weather permitting.

There will be a bit of piping s a spacer which will be to protect

the bolts going through and act as a spacer between the fron

and back sections of the bracket.

Making it in a few sheets of metal means it will be easier to make,

and stronger once welded together so it won't warp and twist.

I'm Diabetic,& disabled BUT!! NOT DEAD YET!!

Re: V6 into a RHD Chrysler Neon mk1

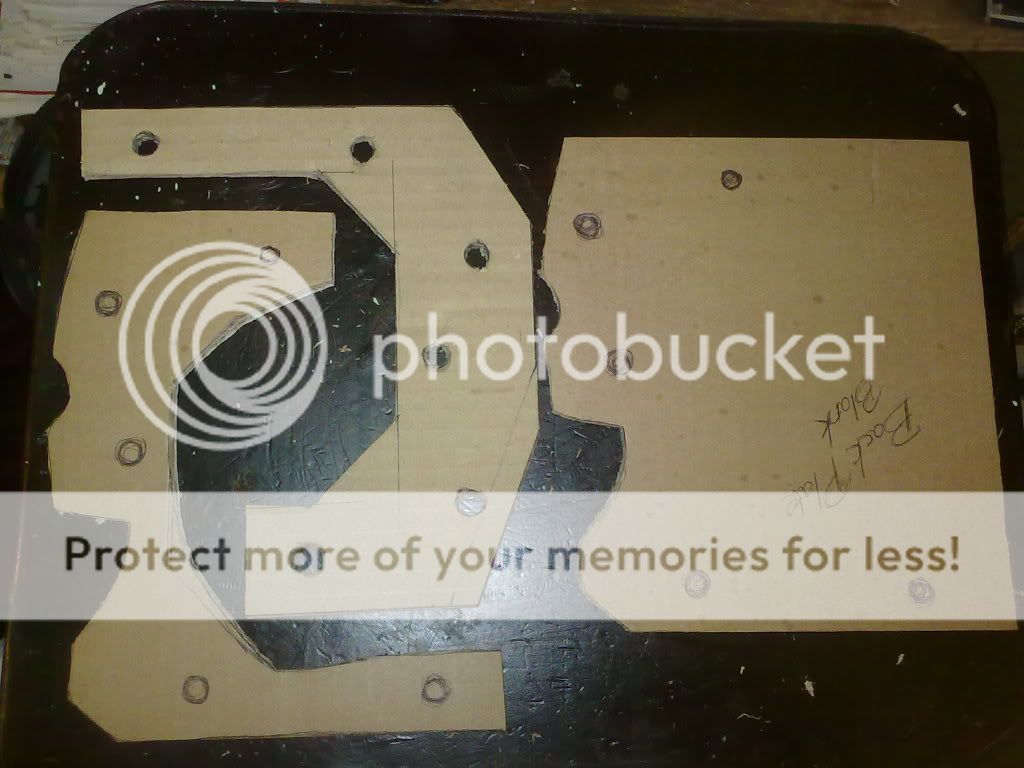

Yesterday I got the grinder out and cut the plates to shape.

However it needs a little weaking.

The belt was put on along with the spring loaded ___________ to see where

things need to be adjusted and to measure for the front plate for the alternator

I will use that bolt witha a spacer to hold the front plate.

The spring loaded _______ has been placed with a tempory bar tohold it in

place as I haven't got a replacement serpintine belt yet.

And because of this bolt and the alternator bracket the spring loaded

_______ won't go any lower.

And the backing plate and spring loaded _______ is cut off the old powersteering bracket off the v6.

While I was waiting on the little laptop trying to remove a virus I got

the partial templates together and made the front alternator bracket

plate.

Yes those are 2 of my inusulin pens! only thing to hand that was

thick enough to act as a bolt at 2am.

Below is the reworked and complete templates that will be used

so that the old parctial templates can be disgarded.

However it needs a little weaking.

The belt was put on along with the spring loaded ___________ to see where

things need to be adjusted and to measure for the front plate for the alternator

I will use that bolt witha a spacer to hold the front plate.

The spring loaded _______ has been placed with a tempory bar tohold it in

place as I haven't got a replacement serpintine belt yet.

And because of this bolt and the alternator bracket the spring loaded

_______ won't go any lower.

And the backing plate and spring loaded _______ is cut off the old powersteering bracket off the v6.

While I was waiting on the little laptop trying to remove a virus I got

the partial templates together and made the front alternator bracket

plate.

Yes those are 2 of my inusulin pens! only thing to hand that was

thick enough to act as a bolt at 2am.

Below is the reworked and complete templates that will be used

so that the old parctial templates can be disgarded.

I'm Diabetic,& disabled BUT!! NOT DEAD YET!!

Re: V6 into a RHD Chrysler Neon mk1

Out came the grinder

Cutting the plates for the front part of the alternator bracket

Then since the LPG brass manifold injector parts came today.

As I will be fitting a new front end kit for the LPG later down the

line I may as well sort the intake manifold out now while I have

it off the car and before it gets painted (colour not decided yet)

Also as the pt cruiser Coolant Filler neck will mean moving the coil

pack I trimmed it's old mounting bracket off the manifold.

And a bump that was done in the manufacturing proccess needed to

come off. I slipped with the grinder too.

While the grinder had a grinding disk not the cutting disk I flattened the

area where the Exhaust Gas Return bolts to the manifold.

So a better seal can be made.

Well it's forecast rain for tonight and tomorrow so it just as well I need to

be in the garage to do the drilling on todays parts.

Drill and tap the holes in the manifold for the LPG injector fittings,

Drill the holes in theplates for the front part of the alternator bracket.

Cutting the plates for the front part of the alternator bracket

Then since the LPG brass manifold injector parts came today.

As I will be fitting a new front end kit for the LPG later down the

line I may as well sort the intake manifold out now while I have

it off the car and before it gets painted (colour not decided yet)

Also as the pt cruiser Coolant Filler neck will mean moving the coil

pack I trimmed it's old mounting bracket off the manifold.

And a bump that was done in the manufacturing proccess needed to

come off. I slipped with the grinder too.

While the grinder had a grinding disk not the cutting disk I flattened the

area where the Exhaust Gas Return bolts to the manifold.

So a better seal can be made.

Well it's forecast rain for tonight and tomorrow so it just as well I need to

be in the garage to do the drilling on todays parts.

Drill and tap the holes in the manifold for the LPG injector fittings,

Drill the holes in theplates for the front part of the alternator bracket.

I'm Diabetic,& disabled BUT!! NOT DEAD YET!!

Re: V6 into a RHD Chrysler Neon mk1

At this rate you'll have the car running by the end of the month, keep up the good work.

J

"Home is where you park it", so the saying goes. That may yet come true..

"Home is where you park it", so the saying goes. That may yet come true..

Re: V6 into a RHD Chrysler Neon mk1

Well it didn't rain all day, but I have run myself into the ground

over the past few days. So only a little done, the drilling od holes

in the plates for the front of the alternator bracket.

Unfortunately, it took longer than expected as all the larger drill bit

were blunt. the smaller ones being ok I driller and tapped the holes

for the lpg injectors. I pray I didn't put them too low.

Before painting I will counter sink those tapped holes for better fitting

and seal.

over the past few days. So only a little done, the drilling od holes

in the plates for the front of the alternator bracket.

Unfortunately, it took longer than expected as all the larger drill bit

were blunt. the smaller ones being ok I driller and tapped the holes

for the lpg injectors. I pray I didn't put them too low.

Before painting I will counter sink those tapped holes for better fitting

and seal.

I'm Diabetic,& disabled BUT!! NOT DEAD YET!!

Re: V6 into a RHD Chrysler Neon mk1

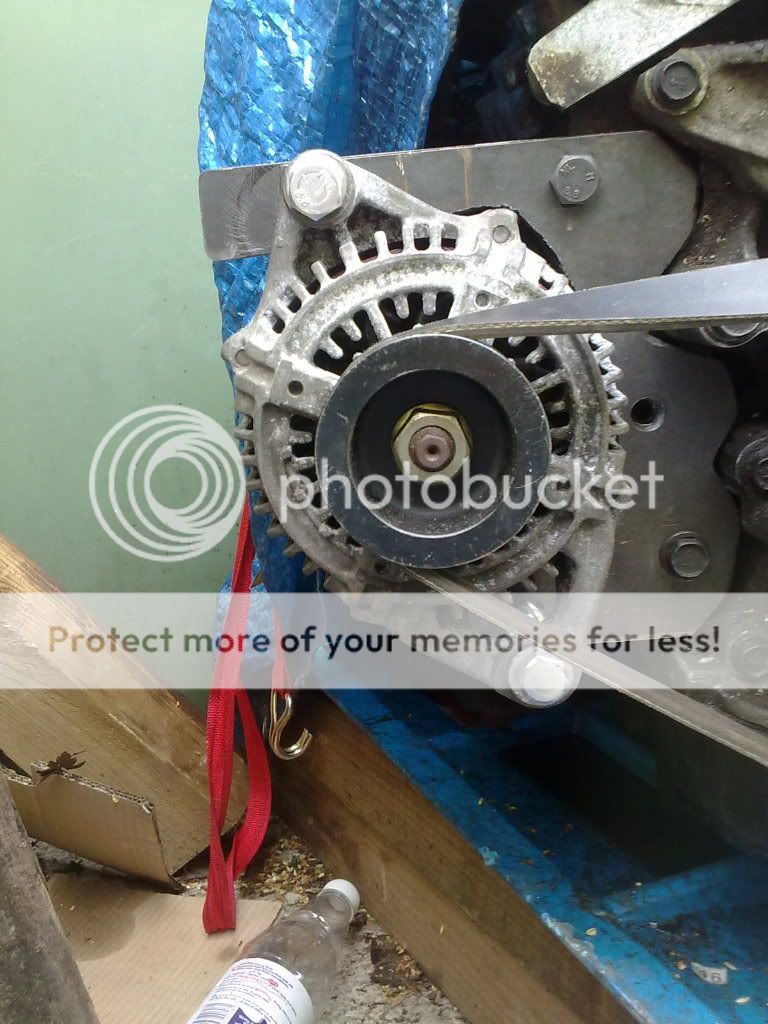

The front plstes of the alternator bracket were put on,

and spacers to line the power steering pump done.

As the pulley on is not what I measured up with orginally on

the power steering pump, the bracket holding the pump will

need to be redone as I used a couple of nuts as spacers for

the current bracket.

The alternator bracket will need a couple of spacer bars to

strenghten it.

However! I will be putting the engine and gearbox back into

the engine bay for a fitting. To see what alterations etc need

to be made and measurements for drive shafts.

and spacers to line the power steering pump done.

As the pulley on is not what I measured up with orginally on

the power steering pump, the bracket holding the pump will

need to be redone as I used a couple of nuts as spacers for

the current bracket.

The alternator bracket will need a couple of spacer bars to

strenghten it.

However! I will be putting the engine and gearbox back into

the engine bay for a fitting. To see what alterations etc need

to be made and measurements for drive shafts.

I'm Diabetic,& disabled BUT!! NOT DEAD YET!!