Re: BRAVE or just FOOLISH RM RESTO

Posted: Sat Oct 29, 2011 8:49 pm

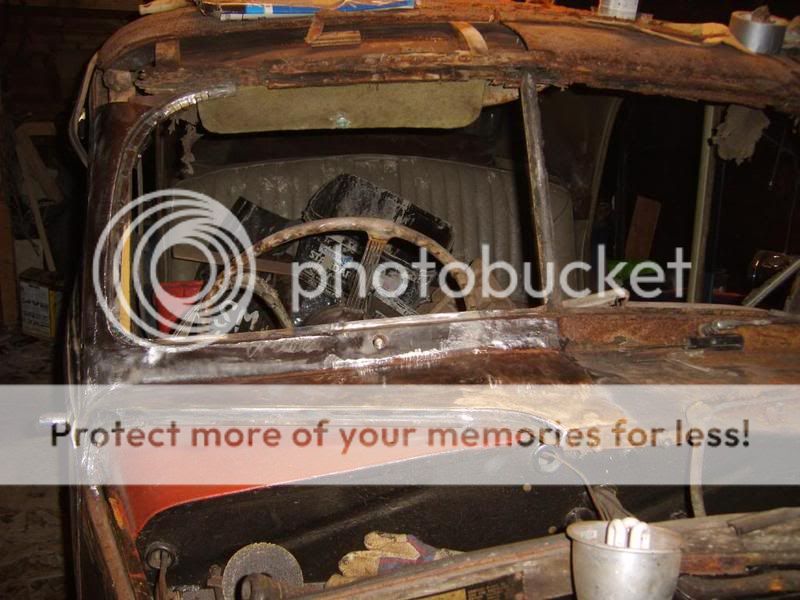

I have to make a heck of a lot of the windscreen panel, so as I don't have access to much other than a simple folder, vice etc it will be done in several sections to gain the (hopefully) correct shape.

First off, some of the old panel is removed, I need to build this in situ to ensure the screen fits and it looks reasonably like the original.

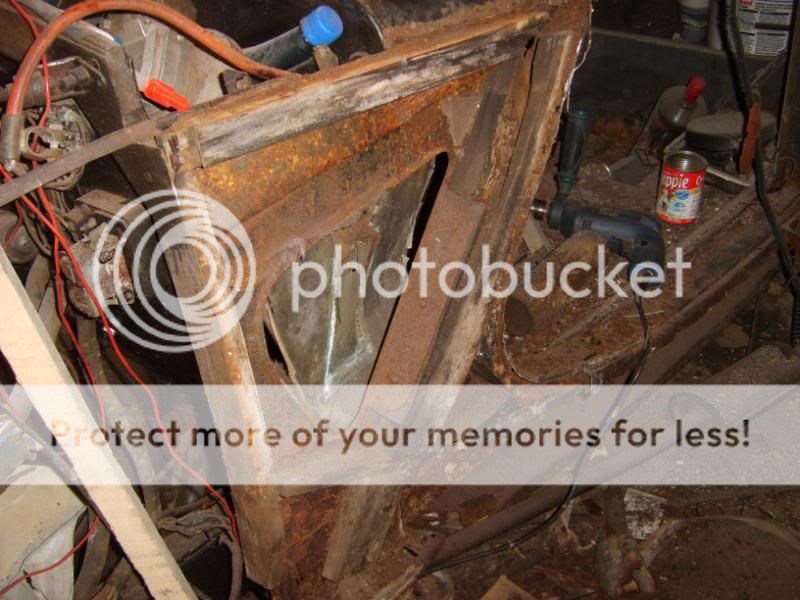

So, off with a section, and a good wire brushing

More rust converter and then some red oxide, see, I said I wasn't just going to use hammerite The area to left of the photo is not as rough as it looks, just the way the camera flash reflected off the wet red oxide where I painted it on the timber.

The area to left of the photo is not as rough as it looks, just the way the camera flash reflected off the wet red oxide where I painted it on the timber.

I'd already dealt with some of the timber around the windscreen frame and A pillar so I can get pretty much straight on with making the new surround at the moment.

This is as far as I am today, the shape is pretty complex and so is about four seperate pieces of folded / bent metal welded together just to make this bottom section, still a couple more pieces of metal to go in and a little more welding to finish before I start on the upright.

The new metal is super shiny and rust free, though the light catches the grinding marks left from my "polishing" it and discolours it in the photos, must try a different setting on the camera, anyway, I'll update when I have a bit more to show.

First off, some of the old panel is removed, I need to build this in situ to ensure the screen fits and it looks reasonably like the original.

So, off with a section, and a good wire brushing

More rust converter and then some red oxide, see, I said I wasn't just going to use hammerite

I'd already dealt with some of the timber around the windscreen frame and A pillar so I can get pretty much straight on with making the new surround at the moment.

This is as far as I am today, the shape is pretty complex and so is about four seperate pieces of folded / bent metal welded together just to make this bottom section, still a couple more pieces of metal to go in and a little more welding to finish before I start on the upright.

The new metal is super shiny and rust free, though the light catches the grinding marks left from my "polishing" it and discolours it in the photos, must try a different setting on the camera, anyway, I'll update when I have a bit more to show.