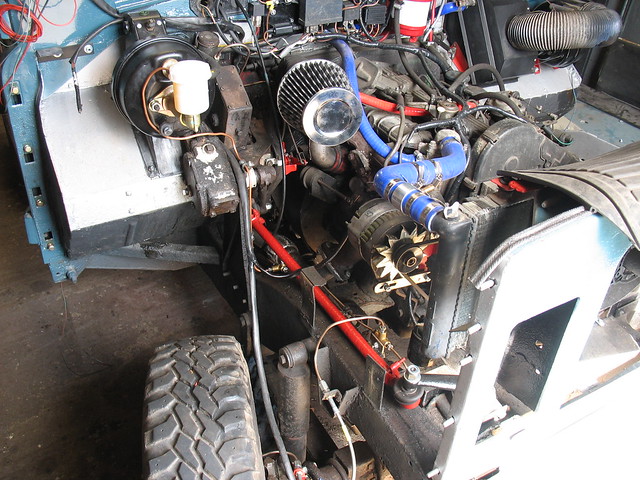

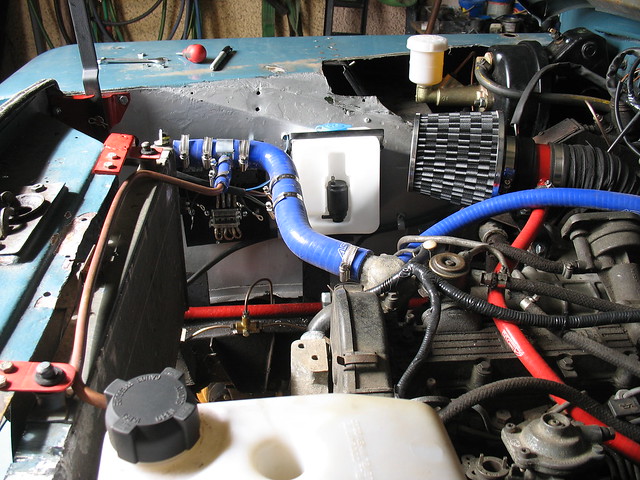

Progress has been slow and not very photogenic! The front lights have been wired up and relays sorted for horns and heater fan (and headlights). The windscreen washers have been wired up and the hose just needs joining up. That means everything in front of the bulkhead has been done (says he!) and is working. I did take a photo of the front yesterday, but it was too sunny for the camera, so I deleted the picture - it was too wet when I got the camera out today!

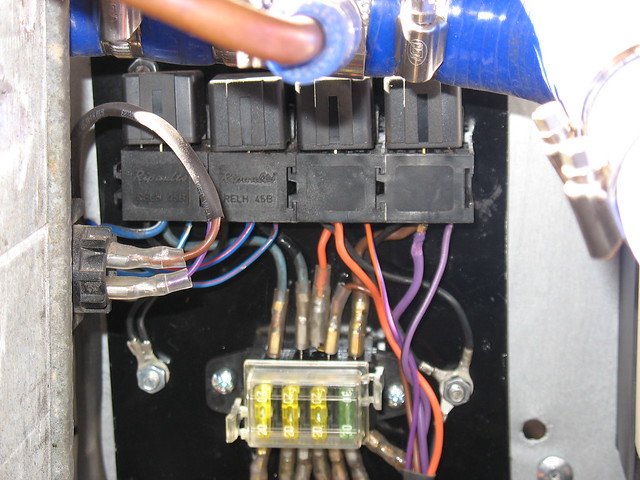

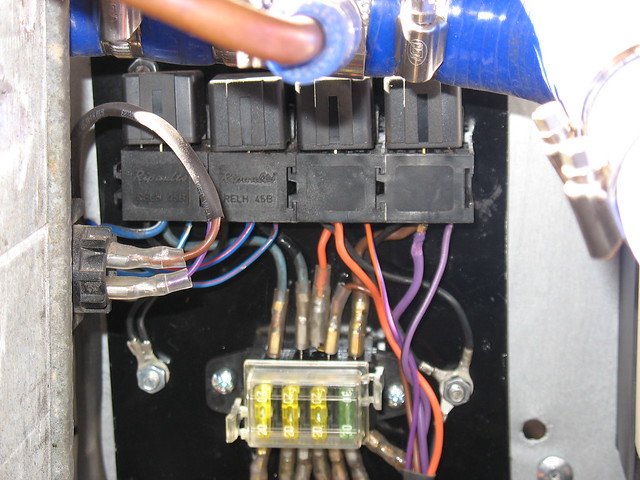

The fuse box and relays (with the radiator switch for the fan on the LH side)

I must remember that I wired the fan switch the wrong way - the live is straight to the switch and the relay's coil earths it, which is bad practice!

I rerouted the wiring for the side lamps and indicators (and repeaters) so they go into the headlamp housing and join a harness there. The harness comes out of the top of the housing and goes through the inner wing to connect to another harness (as per Land Rover design!). However, I need to put some more cable ties on and some clamps on the stays on the inner wings to stop the harnesses falling down and getting messy (the original wiring was a real mess!)

Moving backwards is the way to make progress, so I have done some work on the dashboard! The lower dash had a lot of rust in it and the metal was hardly as thick as a tin can! Not the easiest of stuff to weld (and I am not an Arceye!). However, I have managed to make it almost presentable, though it needs some sanding, seam sealer and paint before I can fit it! I also want to modify it a bit so that the radio and other accessories look as if they are part of the dashboard - that will probably be a next year job.

The large hole is for an access panel to the next "electrical panel", which will have fuse boxes, connection blocks, flasher unit and a relay for switched feeds. One thing's for sure, it will have a few more fuses than the three that were connected!

Note the new angle grinder (and green hose on the "new" pressure washer). I got fed up of swapping from cutting disc to flap wheel (and later, from flap wheel to wired brush), so I bought an Aldi grinder the other day. It's OK for a £19.99 grinder, but nowhere near as handy as the more expensive one!

I spent a long time looking for the fittings for the screen vents this morning; I thought they were with the vents and other dash bits in a box, but no! So I looked at where I had last seen them (on the shelf under the lathe) and then spent quarter of an hour looking before I gave up and got the "odds and sods" storage box out - which had all the screws and bits to put the upper dash back together. This is the box I bought about three weeks ago and emptied the contents of all the aerosol caps and tin cans into it so that the trolley was useable.

Middle section, RH side...

The air was bluer than the Landy!

So I managed to get the top bit of dashboard put together and fitted:

Thinking of things disappearing, I was lighting the fire this evening and had cut up a branch for logs and kindling. I put the wood on the hearth while I went to get something and came back to find a lot had disappeared. A little detective work and a camera caught the culprit coming back for more: